Tire simulation is so good it’s replacing real-world testing

It can now try out new tires in a dynamic sim before making physical test tires.

Tires might be one of the more prosaic parts of a car, but they are undoubtedly among the most important. Bench racers might obsess about powertrain specs, and average consumers mostly want to know that there's wireless charging for their phones, but it's the tires that actually make contact with the road. Without them, no one is going anywhere. At least not very far.

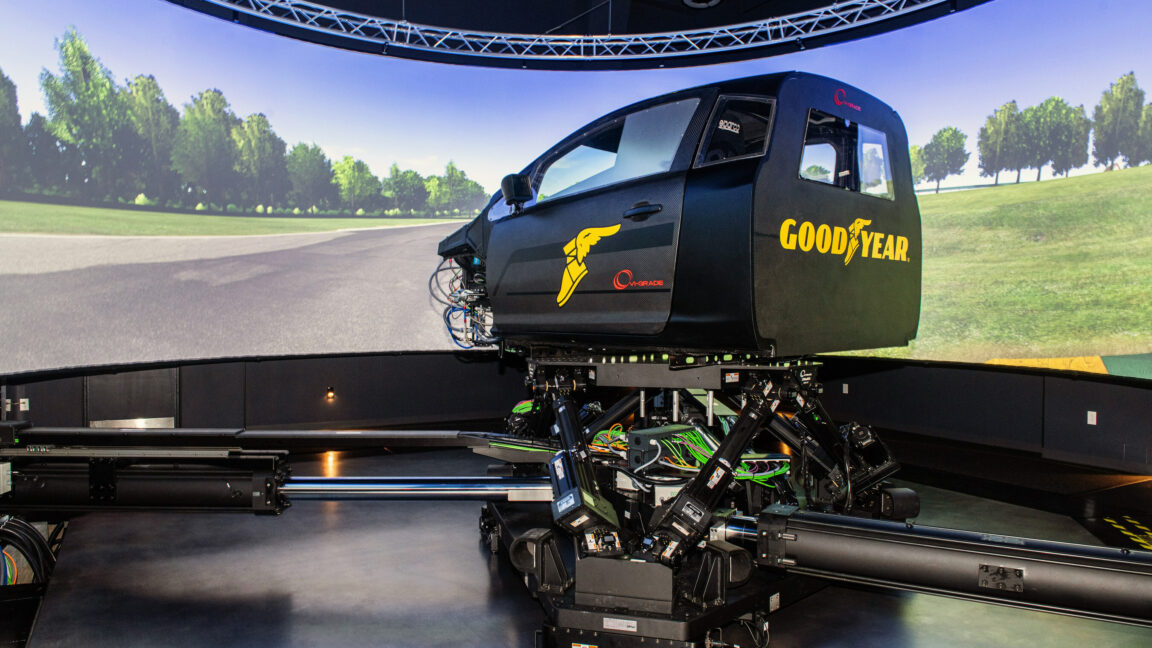

In the past, tires have been considered somewhat mysterious, with secret blends of rubber, carbon, and other stuff combined with clever arrangements of belts and wires to hold the whole thing together as it rotates faster and faster without flying apart. These days, we know an awful lot about how tires work. Or at least tire companies like Goodyear do, having amassed enough testing data to be able to simulate them accurately enough to shave months off a development schedule.

In fact, the use of simulation in tire research and development has quite a long history. Chris Helsel, who is now Goodyear's CTO, joined the company back in 1996; he was hired as part of a tiny team doing computer tire simulation. "At Goodyear in '96, it felt like almost late to the party in terms of doing what we call finite element analysis, which is basically breaking a large structure down into little parts," Helsel said.